Momenta's Take: The AI Revolution in Manufacturing

Ed Maguire

The AI Revolution in Manufacturing:

A Momenta Perspective

Artificial intelligence is having a transformative effect across the economy, and manufacturing is where some of the most revolutionary impacts occur.

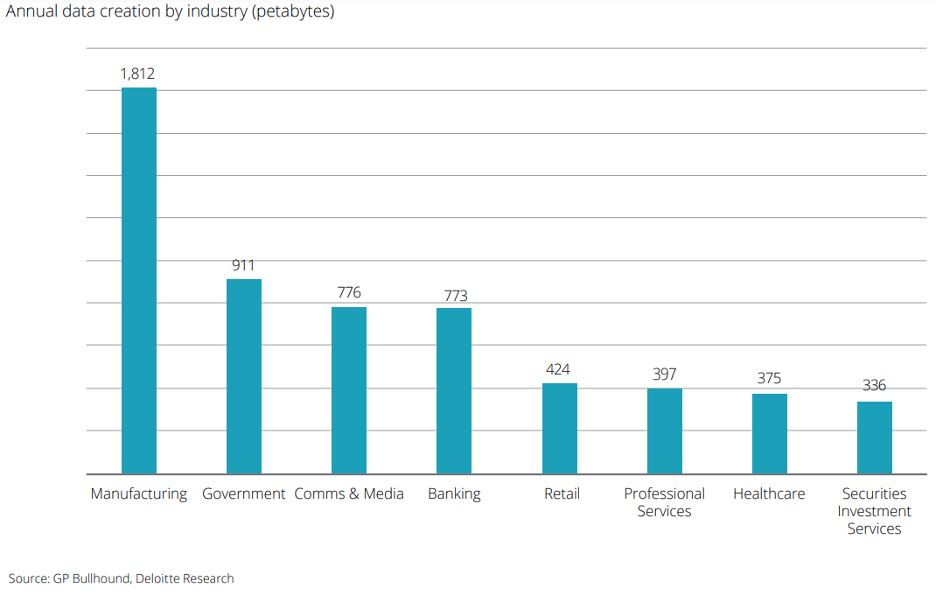

AI is so promising in manufacturing because of the bounteous quantities of data that can be explored and analyzed. Compared to other industries, manufacturing generates significantly more data, according to a study by Deloitte, as a result of diverse sources ranging from sensor data to time series data stored in an operational historian to supply chain, quality assurance, and more. This gives rise to opportunities for advanced machine learning and AI technologies to identify patterns and correlations that would otherwise be difficult or impossible to uncover.

This gives rise to opportunities for advanced machine learning and AI technologies to identify patterns and correlations that would otherwise be difficult or impossible to uncover.

According to an analysis by Bain, strategic M&A declined by 6% in 2023, and the biggest obstacle was buyers and sellers struggling to close the gap in valuations. Private equity exits declined 44% in value and 22% in volume in 2023. Deal activity also differed across sectors. While tech saw the greatest declines, healthcare, energy, and natural resources activity showed particular strength.

Of course, ensuring the data's integrity is one of the most critical factors in ensuring the efficacy of AI solutions. Aperio is a Momenta portfolio company whose platform automates the validation of operational data in industrial organizations, addressing data completeness, content, and metadata context, using AI and ML to scale and prioritize data quality issues.

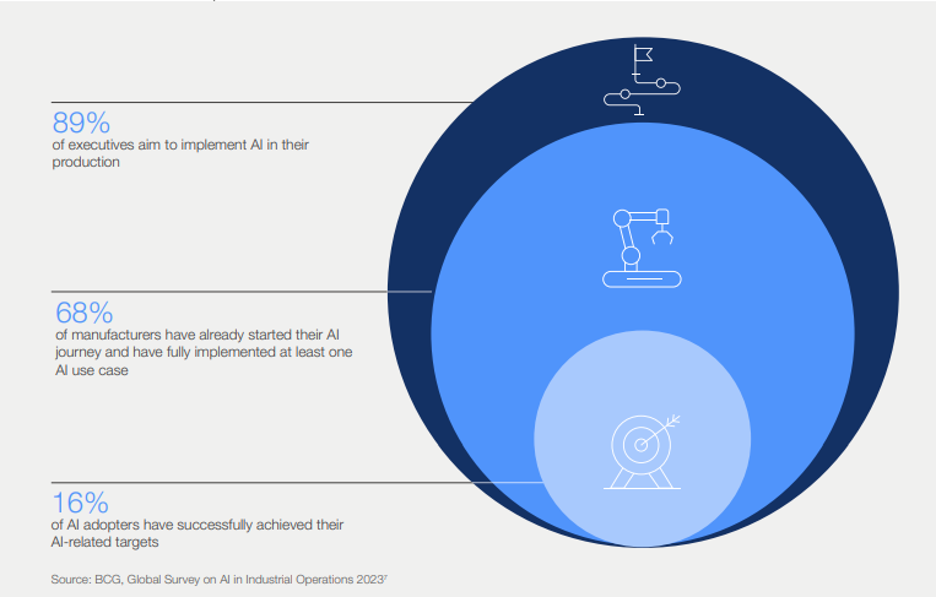

We are still in the early stages of AI adoption, and interest levels are high. According to a recent BCG study, 89% of executives intend to implement AI in production, while only 16% of adopters have successfully achieved AI-related targets.

As technological innovation accelerates, from machine learning to deep learning to Generative AI, the potential value-creation opportunities are significant. According to ABI Research, the adoption of generative AI is forecast to unlock $10.5 billion in new revenues for the manufacturing industry by 2033.

However, adoption challenges are both organizational and technical. A study from BCG found that 88% of executives cite a lack of AI-related technology infrastructure as a significant challenge. In comparison, 92% cite the lack of an AI-related people and organization foundation as a challenge.

Accelerating Innovation, Quality, and Operations

AI technologies enable manufacturers to optimize design and production processes, improve quality control, proactively manage equipment to avert costly downtime, and enhance supply chain management. ABI sees the most significant revenue lift from generative AI in manufacturing coming in waves as the technology matures, most impactful when deployed into four domains of manufacturing: design, engineering, production, and operations.

Revolutionizing Manufacturing from the Ground Up

At Momenta, our investment approach focuses on technologies and teams that harness innovations to deliver multi-faceted value to stakeholders. Here is a sample of how our portfolio companies use AI to revolutionize manufacturing.

- Operations Optimization – Large-scale manufacturing involves a deft choreography of sourcing materials, scheduling, maintenance, quality assurance, and yield analysis. Minds.ai applies AI and Machine Learning to semiconductor manufacturing to address complex scheduling and resource allocation challenges. The company's solutions enhance productivity and perform tasks autonomously, freeing experts to focus on higher-value activities.

- Predictive Maintenance - The integration of AI into predictive maintenance accelerates the ability for manufacturers to analyze equipment data in real-time to predict and prevent potential failures before they occur. This proactive approach reduces downtime and extends the lifespan of assets, resulting in significant cost savings for manufacturers. Shoreline IoT offers a cloud-managed Connected Asset Performance Management solution that helps manage "dark assets" through AI-driven condition monitoring.

- Quality Control and Inspection – Inspections for quality control have historically relied on highly trained workers to detect defects and anomalies visually. Still, with the adoption of computer vision and machine learning algorithms, these tasks can now be automated and performed with far greater accuracy. Overview AI has developed a computer vision platform that enables quality control and industrial traceability via automated visual inspection. Smartex employs computer vision to allow textile manufacturers to detect real-time defects inside circular knitting machines during production, enabling manufacturers to spot problems immediately.

- Energy Management and Resource Optimization – AI technologies can help manufacturers reduce resource waste, energy consumption, and raw materials. Tvarit utilizes AI models for prescriptive quality and energy to significantly reduce energy consumption and increase yield in metal casting operations. Manufacturers can achieve sustainability goals by implementing AI-driven strategies while enhancing overall operational performance.

The AI revolution in manufacturing is well underway, with Momenta's portfolio companies leading the charge towards a more efficient, agile, and data-driven industry. By harnessing the transformative power of AI, manufacturers can unlock new opportunities for innovation, growth, and sustainability in the years to come.

Momenta is the leading Industrial Impact venture capital firm, accelerating digital innovators across energy, manufacturing, smart spaces, and supply chain. For over a decade, our team of deep industry operators has helped scale industry leaders and innovators to improve critical industries, the environment, and people's quality of life.