Momenta's Take: Smart Manufacturing: AI and Data Analytics Revolution

Ed Maguire

Making Smarter: A New Era of Intelligent Manufacturing is Underway

We are beginning a new era of Intelligent Manufacturing, where AI is set to revolutionize industrial and manufacturing processes, driving optimization, automation, and unparalleled efficiency. Digital transformation is at the heart of the transition, and while robotics and automation play pivotal roles, Artificial Intelligence software is driving the most meaningful innovation. Notably, a substantial portion of this transformation arises from the strategic re-shoring of manufacturing operations in response to supply chain vulnerabilities. A recent Deloitte report from November 2022 reveals that 62% of U.S. manufacturers are re-shoring or near shoring their production capacities.

Amid this manufacturing renaissance, data analytics and AI applications take center stage, equipping manufacturers with the tools to refine processes, enhance product quality, and secure a competitive edge. But what fuels their success, and what challenges and opportunities lie ahead?

Our forthcoming blog post takes you on an illuminating journey through the most innovative AI solutions in manufacturing, crafted by Momenta's visionary portfolio companies. These pioneers apply AI to various manufacturing aspects, from quality control to predictive maintenance, and process automation, delivering real-world solutions that create tangible value and shape the industry's future. Don't miss the chance to stay at the forefront of the digital factory revolution. Dive into this blog post and be part of the conversation that's shaping the future of manufacturing!

Investments in Digital Factory Transformation are Booming.

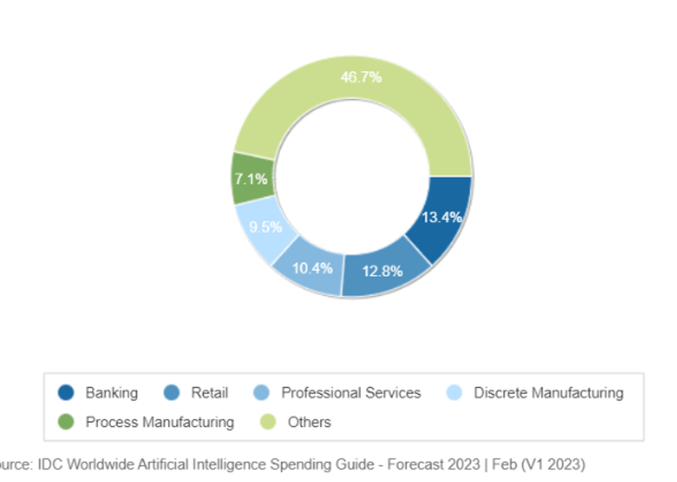

A large amount of capital flows into manufacturing, with significant implications for investors, startups, and established firms. According to the PwC Digital Factory Transformation Survey 2022, industrial companies are investing $1.1 trillion a year in digital transformation solutions. By one forecast, the market for AI in Manufacturing is forecast to grow at a CAGR of 55% from $1.5bn in 201size, estimated to be worth 1.5 billion dollars in 2021, to over $17bn by 2027. IDC forecasts that combined investments by manufacturers will account for 16.6% of $154 billion in 2023 global AI sales.

Data is the Power Source for Intelligent Manufacturing

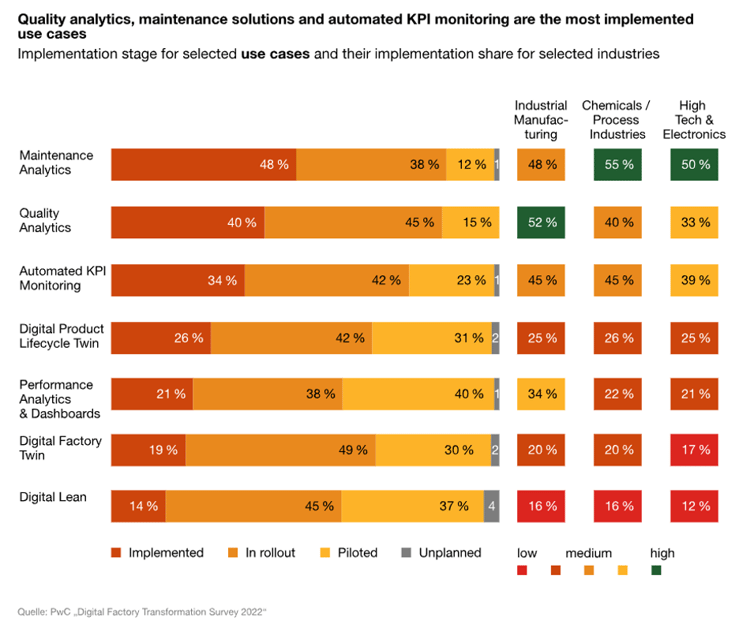

According to PwC, the most implemented use cases underway are all focused on leveraging data analytics in creative ways.

AI will play a crucial role in advancing value in manufacturing and industrial scenarios, including:

- Predictive Maintenance – AI can more quickly identify signals to avert unplanned downtime, optimizing machinery lifespan and minimizing disruptions.

- Process Optimization - AI algorithms make real-time adjustments to enhance product quality, reduce energy consumption, and maximize efficiency.

- Quality Control - AI-powered systems can inspect products and spot defects difficult to detect with the naked eye, ensuring better quality and reducing waste.

- Supply Chain Management - AI can help forecast demand, optimize inventory levels, and streamline logistics.

- Energy Efficiency - AI can optimize energy consumption and reduce environmental impact by adjusting equipment usage based on demand and real-time energy costs.

Innovators Charting New Paths

At Momenta, we are focused on how technological innovations will shape the future of manufacturing. Several notable portfolio companies are charting new paths. One of the foundations for effective analytics and AI is data quality. APERIO is a leader in industrial data integrity solutions. Its AI-powered data observability solutions validate operational data at scale to improve data accuracy, security, and value, allowing for smarter business decisions based on real-time, trusted, superior data.

AI-powered computer vision plays a key role for two innovative companies. Overview: AI leverages computer vision for automated quality control and factory traceability, helping to make products that allow for transformative changes in factory operations. Smartex has developed hardware-enabled, machine-vision-driven software to detect textile defects in real time, helping to reduce textile waste, CO2 emissions, energy, water, and capital expenditures.

Other firms are targeting the specific needs of specialized manufacturing. Minds.ai is applying AI to semiconductor manufacturing optimization and autonomy, driving significant productivity and waste reduction advancements.

Preparing for the Transition Ahead

There is a lot of work ahead for manufacturers to harness the power of data analytics and AI effectively, and the transition is in the early stages. According to Rockwell Automation’s 2023 State of Smart Manufacturing Report, 1/3 of existing manufacturing data goes unused, and many manufacturers lack the ability to use data to make decisions. In order to address the challenges, the World Economic Forum and BCG have launched AI-powered Industrial Operations, a new global initiative that seeks to raise awareness of the potential offered by AI applications, along with providing frameworks, resources, and support to help manufacturers on the path to implementation.

As the wave of investment continues to surge, there is a pressing need to embrace AI. However, without careful planning, there are potential risks of failure, wasted time, and resources. By focusing on achieving small victories through targeted solutions, manufacturers can maintain maximum flexibility and forge partnerships with the future's emerging leaders.

Momenta is the leading Industrial Impact venture capital + growth firm. We accelerate entrepreneurs and leaders devoted to the digitization of energy, manufacturing, smart spaces, and supply chains. Since 2012, our team of deep industry operators have made over 100 investments in entrepreneurs and helped scale over 150 industry leaders via our award-winning executive search and strategic advisory practices.