Portfolio Insights

Eigen Innovations - The 5 Levels of Autonomous Manufacturing

Ken Forster

At Momenta we bring a unique combination of experience to help founders and management teams meet the challenges of building and sustaining start-ups, enabling companies to realize their full potential. We're proud of our portfolio companies and in the coming months we will be featuring the insights and experiences of a portfolio company each month. It's a great opportunity to share their first hand knowledge with the Momenta Community.

This post is guest written by Scott Everett, CEO of Eigen Innovations. Founded in 2012, Eigen Innovations was born from the belief that the true potential of Artificial Intelligence within manufacturing would only be discovered by introducing tangible uses cases on the factory floor. Eigen empowers their customers to introduce different levels of autonomy as they teach, test and trust their machines to ultimately operate with minimal human intervention. They start by focusing on the machines and lines that drive the biggest costs and the highest cycle times, allowing for an immediate return on investment and, ultimately a scalable path to autonomous manufacturing.

|

Scott Everett

CEO |

You can never underestimate the power of a good analogy

As a start-up founder focused on deploying AI solutions for industrial manufacturing, I have run through the gambit of IoT and AI rhetoric when talking to customers. The biggest challenge for me has always been finding a concrete way to explain how something as abstract as distributed artificial intelligence can be relevant to the factory floor.

Industry knows the buzz words, and in general, understands that there is a technological revolution on its way. However, unless you can boil down the abstract concepts into a very clearly defined journey and a sequence of steps that deliver tangible value at each stage, no one really cares.

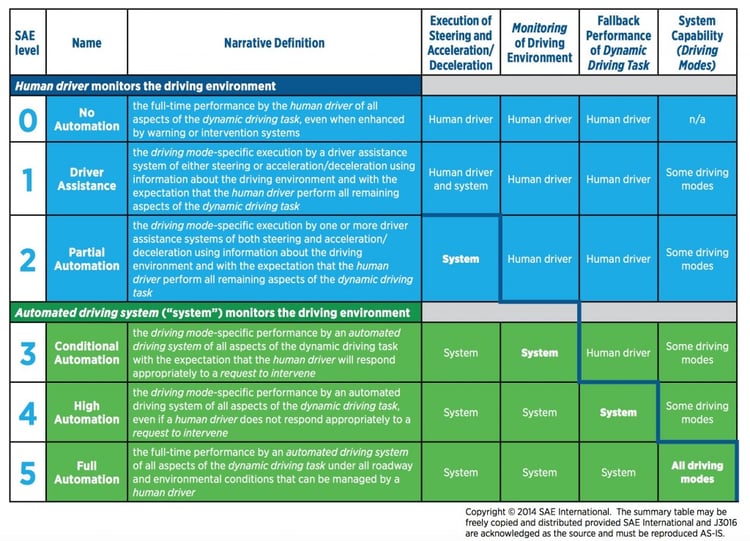

The road to clarity for me was actually paved by the autonomous driving industry. During the quest for driver-less vehicles, the industry helped us define distinct levels of autonomy:

The fundamental relevance of these distinctions is that to progress through the levels of autonomous driving there is a growing complexity of data and intelligent computing requirements to sense, interpret and react to real world scenarios. The vehicle must become more aware of its surroundings and more flexible in its judgments. The same is true for autonomous manufacturing. Rarely does a machine operate in isolation from other systems. Machine learning applications that deliver real and tangible ROI within the manufacturing environment are based on a distributed intelligence model and require continuous interaction between:

- An AI algorithm

- A dataset unique to the machine including machine data, upstream data and downstream data

- Insights from factory subject matter experts who innately understand the intricacies of the machine’s intended processes, and have a quality driven or performance expectation from the process

The 5 Levels of Autonomous Manufacturing

Here’s how I think about the various levels of Autonomous Manufacturing:

Level 0

Level 0

The machine is human operated

Level 1

Level 1

A machine that benefits from basic monitoring tools with simple thresholds to reject parts.

Level 2

Level 2

Assumes AI inspection for complex quality metrics and machine performance are deployed. Unsupervised learning helps the user discover quality and performance variability.

Level 3

Level 3

Upgrades AI inspection to an AI prediction of quality and machine performance occurs based on multi-sensor integration, an automated DOE and/or diverse data collection.

Level 4

Level 4

Takes that prediction and introduces an AI recommendation engine suggesting operating parameters given normal or known conditions.

Level 5

Level 5

The machine becomes an AI problem solving engine that can adapt to unknown operating conditions without human supervision. The system implements multi-objective optimization in real-time.

Levels provide a scalable deployment path

Attaining these levels is not only realistic, it also provides a scalable path for manufacturers to deploy autonomy within their factories. When I talk to our customers, this is key. A disciplined path not only delivers tangible and immediate ROI, it also lends itself to greater adoption. We all know none of this works unless the collective team is on board and excited.

Over the last 5 years, as CEO of Eigen, I have had the privilege of witnessing firsthand how powerful this evolution can be. I see Level 1’s strive to become Level 2’s and Level 3’s pushing the envelope to become Level 5’s. Factory SME’s are putting points on the board within days and months. And it’s all because a very simple analogy allowed them to get back to the basics and solve very complex problems by breaking it down into a very deliberate sequence of steps. No more buzz words, no more abstract concepts. Just a series of steps to deliver powerful results. How cool is that?

Momenta Partners encompasses leading Strategic Advisory, Executive Search, and Investment practices. We’re the guiding hand behind leading industrials’ IoT strategies, over 100 IoT leadership placements, and 17+ young IoT disruptors. Schedule a free consultation to learn more about our Connected Industry practice.