Momenta's Take: Unlocking the Industrial Metaverse

Ed Maguire

Unlocking the Industrial Metaverse

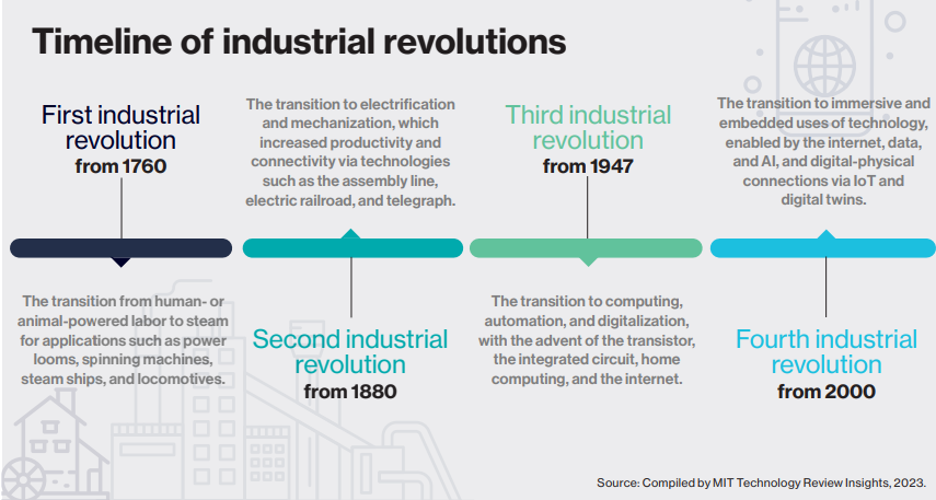

One of the most powerful concepts in the Digital Industry is the "industrial metaverse," which converges several powerful and emerging technologies. While the metaverse concept is most commonly associated with consumer applications such as gaming, commercial use cases are gaining traction and represent a significant market opportunity.

At the NVIDIA GTC conference this past week, keynotes and sessions highlighted the industrial metaverse's powerful and compelling use cases.

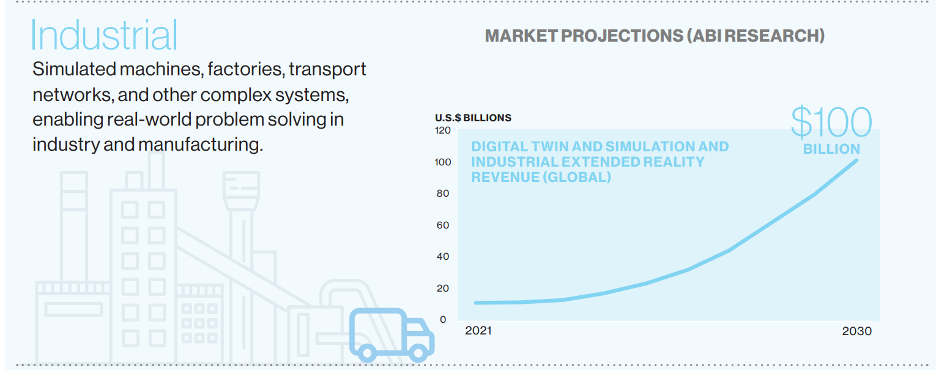

ABI Research estimates that the industrial metaverse market, encompassing digital twins, augmented field service, and predictive maintenance use cases, could reach $100 billion by 2030. This is larger than the $50 billion consumer metaverse and the combined $30 billion enterprise metaverse

The industrial metaverse refers to the creation of a 3-dimensional virtual representation of a machine, process, or entire facility that allows users to view, interact with, and model designs and changes in digital format – which can then be implemented in the physical world. According to Deloitte: "The industrial metaverse is the convergence of individual technologies that, when used in combination, can create an immersive three-dimensional virtual or virtual/physical industrial environment. As technology evolves, the industrial metaverse will likely allow access to these immersive 3D environments from any internet-connected device, including virtual reality (VR) and augmented reality (AR) devices, as well as smartphones, tablets, laptops, and equipment, from anywhere in the world."

The industrial metaverse emerges from several technologies. According to ABI, key enabling technologies include connectivity (5G/6G), 3D/Web3 (including 3D content generation), AR/VR and mixed reality, compute, AI/ML, and IoT.

The industrial metaverse can trace its origins to digital twins, virtual replicas of physical assets, processes, and systems that have been used to simulate and analyze real-world scenarios. Digital twins can enable valuable industrial capabilities such as real-time monitoring, predictive maintenance, and optimization by providing a virtual representation of physical entities. Litmus Automation is a Momenta portfolio company that provides Digital Twins inside its Litmus Edge and Litmus Edge Manager. Because Litmus is the source of raw data from 250+ industrial protocols for its own Digital Twins Framework, asset modeling and instances of digital twins can work on the same platform.

With the addition of advanced 3D rendering technologies, VR headsets, and the massive processing power enabling rapid advancements in AI and Machine Learning, the industrial metaverse enables promising opportunities.

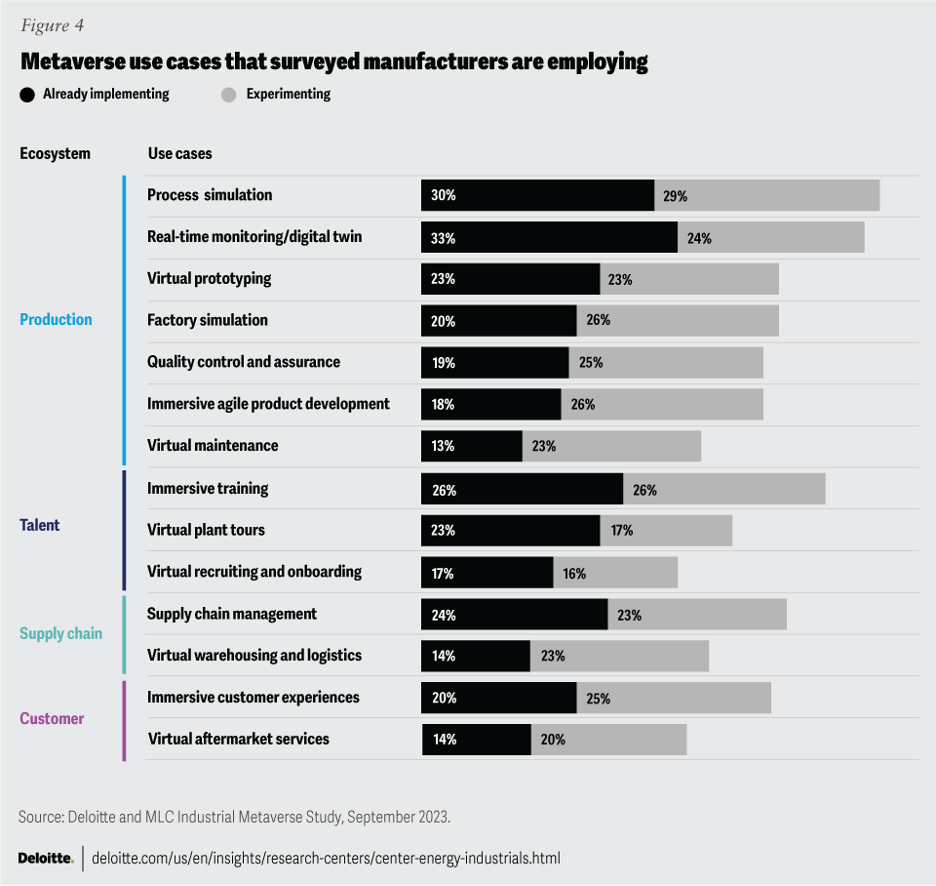

There are multiple use cases for industrial metaverse across various industries. A 2023 study by Deloitte found that 92% of executives surveyed said that their company is experimenting with or implementing at least one metaverse-related use case, and, on average, they are currently running more than six.

According to ABB, the industrial metaverse can improve plant operations using virtual engineering and co-simulation, increasing agility and resilience of production facilities through continuous optimization, reducing order delivery times through fully connected supply networks, optimizing energy consumption, and improving worker understanding of their role in the production process through visualizing work processes using extended reality (XR).

Some of the most promising use cases include:

- Remote Monitoring and Maintenance: The industrial metaverse can allow for more intuitive and accessible monitoring of equipment health, performance, and operational status. This enables predictive maintenance, minimizing downtime, and optimizing assets.

- Simulation and Training: Metaverse virtual environments enable immersive training through simulation, allowing operators and field service workers to gain expertise in complex machinery and procedures in a safe and controlled setting.

- Supply Chain and Facilities Optimization: Virtual replicas of supply chain networks and facilities enable real-time visibility, predictive analytics, and scenario planning, optimizing inventory management and logistics operations. NVIDIA demonstrated the virtual replica of a complete warehouse operation, including inventory, workers, and workflows, enabling operators to optimize operations and immediately respond to real-time disruptions.

- Digital Prototyping and Design: Industrial metaverse applications allow for fully immersive 3D simulations. Virtual prototyping and design simulations enable rapid iteration, optimization, and validation of product designs. NVIDIA and Siemens recently demonstrated how generative AI can power complex data visualization, enabling sustainable shipbuilder HD Hyundai to develop new products.

- Collaborative Workspaces: Immersive virtual collaboration platforms enable global teams to collaborate, interact, and co-create in shared virtual environments.

Unlocking the Industrial MetaverseOne of Momenta's innovative portfolio companies is Axiom Cloud, which provides a cloud analytics solution that digitally transforms how cooling systems are powered, operated, and maintained. Axiom Cloud's Facilities Analyzer solves painful energy and maintenance problems for refrigeration by providing store owners with a dashboard for real-time data from all cooling assets; leveraging predictive analytics allows them to anticipate potential issues.

While the industrial metaverse can be seen as the evolution of digital twins, the potential applications extend far more broadly across industries. Major technology leaders, including Siemens, Microsoft, PTC, and others, are investing in technologies, partnerships, and solutions. While still in the early stages of evolution, we at Momenta anticipate powerful implications for digital industry as the industrial metaverse evolves.

Momenta is the leading Industrial Impact venture capital firm, accelerating digital innovators across energy, manufacturing, smart spaces, and supply chain. For over a decade, our team of deep industry operators has helped scale industry leaders and innovators to improve critical industries, the environment, and people's quality of life.